To clean a cotton candy machine, first ensure it is unplugged and cooled down. Then, disassemble and wash the parts with warm, soapy water thoroughly.

Maintaining cleanliness in your cotton candy machine is crucial for ensuring its longevity and quality performance. Regular cleaning helps prevent clogs, residue buildup, and bacterial growth, which can impact the taste and safety of your cotton candy. Following proper cleaning procedures also helps maintain the machine’s efficiency and extends its lifespan.

We will provide you with simple steps to effectively clean and maintain your cotton candy machine, allowing you to enjoy sweet, fluffy treats for years to come.

Credit: m.youtube.com

Why Clean Your Cotton Candy Machine

Regular cleaning and maintenance of your cotton candy machine are essential for several reasons. Not only does it ensure the longevity and optimal performance of the machine, but it also helps prevent contamination and maintain the quality of your cotton candy. By keeping your machine clean, you can provide your customers or guests with delicious and hygienic cotton candy every time. In this section, we will explore the importance of cleaning your cotton candy machine in detail.

Preventing Contamination

One of the main reasons for cleaning your cotton candy machine regularly is to prevent contamination. With repeated use, your machine can accumulate dust, dirt, and leftovers from previous batches. These particles can contaminate the fresh cotton candy, compromising its taste and cleanliness.

By thoroughly cleaning the machine after each use, you can remove any leftover sugar residue, food particles, or debris that may have accumulated. This prevents the growth of bacteria or mold, ensuring that the cotton candy you serve remains safe and uncontaminated.

Maintaining Machine Performance

Cleaning your cotton candy machine is also crucial for maintaining its performance. Over time, the buildup of sugar, syrup, and residue can affect the machine’s spinning head, motor, and other components. This can lead to clogs, uneven spinning, or even damage to the machine.

Regular cleaning and maintenance help prevent these issues and ensure that your cotton candy machine operates smoothly every time. By keeping it free from blockages and maintaining the cleanliness of its parts, you can enjoy consistent, fluffy cotton candy without any disruptions or malfunctions.

Additionally, cleaning your cotton candy machine allows you to inspect and identify any wear and tear. Regular maintenance enables you to address minor repairs or replace worn-out parts before they lead to more significant issues, saving you time and money in the long run.

In conclusion, cleaning your cotton candy machine plays a crucial role in preventing contamination and maintaining its performance. By establishing a routine cleaning schedule and following the manufacturer’s instructions, you can ensure that your machine delivers delicious cotton candy that is both safe and enjoyable for everyone.

Credit: m.youtube.com

Cleaning Supplies You Will Need

To ensure your cotton candy machine functions effectively and produces delicious treats, it’s essential to keep it clean. Here are the cleaning supplies you will need:

Warm Water And Soap

Warm water and soap are effective for removing sugar residue and other sticky debris from the cotton candy machine components. Make sure to use a mild, unscented soap to avoid leaving any unwanted flavors or odors.

Vinegar Solution

A vinegar solution is an excellent natural cleaning agent, capable of breaking down tough, sugary deposits in the machine. Mix equal parts of white vinegar and water in a spray bottle for an efficient cleaning solution.

Soft Cloth Or Sponge

Use a soft cloth or sponge to gently wipe down the surfaces of the cotton candy machine. Avoid using abrasive materials that could scratch or damage the machine.

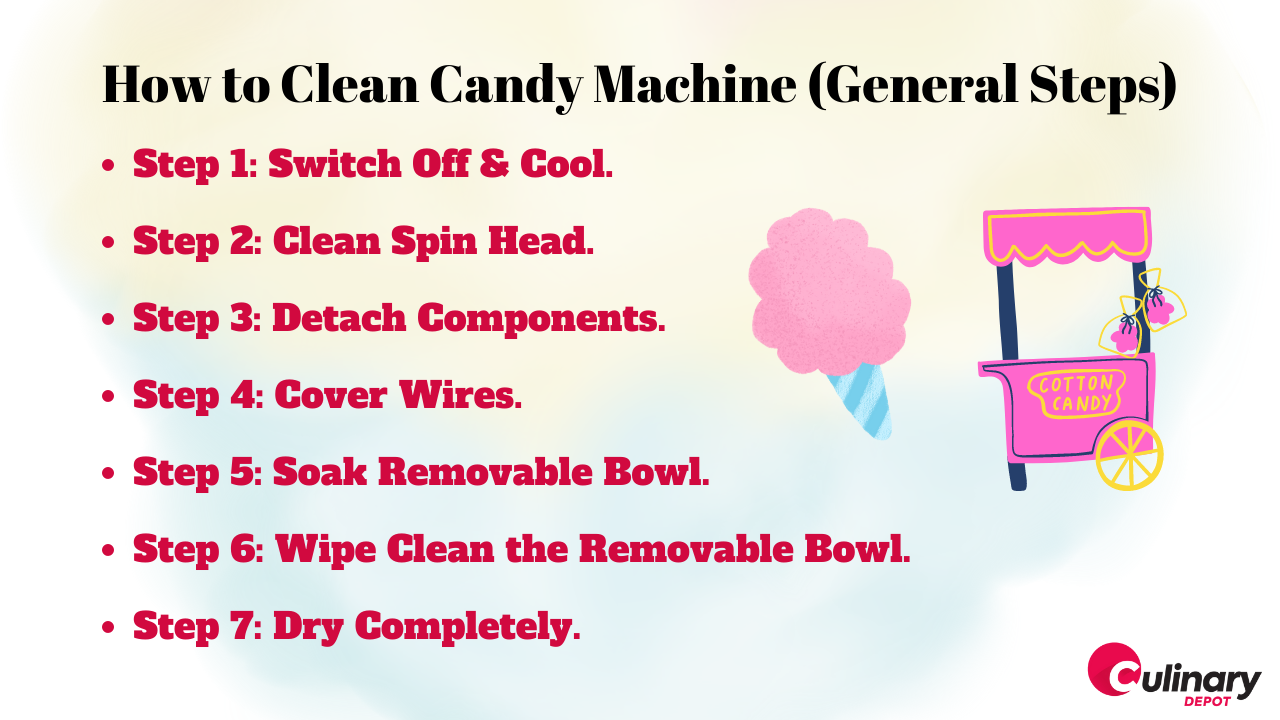

Step-by-step Cleaning Process

Here is a simple guide on how to clean your cotton candy machine Step-by-Step Cleaning Process:

Unplug And Disassemble The Machine

1. First, unplug the machine and dismantle all removable parts.

2. Ensure to follow the manufacturer’s instructions while disassembling.

Wipe Down All Surfaces

1. Use a damp cloth with mild soap to wipe all exterior surfaces.

2. Avoid getting any electrical components wet during this process.

Clean The Spinner Head

1. Remove any sugar residue or debris from the spinner head.

2. Use a toothpick or a small brush to clean hard-to-reach areas thoroughly.

Wash And Rinse The Bowl

1. Detach the bowl and wash it with warm, soapy water.

2. Rinse the bowl thoroughly to remove all soap residue.

Dry And Reassemble The Machine

1. Use a clean cloth to dry all parts before reassembling the machine.

2. Follow the manufacturer’s guidelines to properly put the parts back together.

Credit: www.culinarydepotinc.com

Regular Maintenance Tips

Regular maintenance of your cotton candy machine is essential to keep it clean and functioning smoothly. Follow these tips to ensure proper cleaning and maintenance for a longer lifespan of your machine.

Regular maintenance is key to ensuring your cotton candy machine operates efficiently and produces the best results. Follow these simple tips to keep your machine clean and in top condition.Remove Spun Sugar Buildup After Each Use

Check And Clean Heating Elements

Store The Machine Properly

– Disassemble and clean parts before storing – Store in a dry place to prevent corrosionBy following these maintenance tips, you can ensure your cotton candy machine is always ready to create sweet treats for your customers.Deep Cleaning And Troubleshooting

When it comes to maintaining your cotton candy machine, deep cleaning and troubleshooting are essential. Regular maintenance can help you ensure that your machine operates smoothly and continues to produce delicious cotton candy. Below, we’ll cover how to perform a deep clean using a vinegar solution and address common issues that may arise.

Deep Clean With Vinegar Solution

To deep clean your cotton candy machine, you’ll need a vinegar solution. Here’s a simple step-by-step guide to help you get started:

- Turn off the machine and unplug it from the power source.

- Remove any remaining cotton candy and disassemble the machine according to the manufacturer’s instructions.

- Mix a solution of water and vinegar in equal parts.

- Use a soft cloth or sponge to wipe down the interior and exterior of the machine with the vinegar solution.

- Rinse the machine with clean water to remove any vinegar residue.

- Allow the machine to air dry completely before reassembling and using it again.

Addressing Common Issues

Even with regular maintenance, you may encounter some common issues with your cotton candy machine. Here are a few troubleshooting tips for addressing these problems:

Cotton Candy Not Forming Properly

- Ensure that the machine’s heating element is reaching the correct temperature.

- Check that the sugar floss is not too moist, as this can affect the formation of cotton candy.

- Clean the machine’s spinning head as it may be clogged with sugar residue.

Machine Overheating

- Check for any obstructions in the machine’s ventilation system and remove them.

- Allow the machine to cool down for a sufficient amount of time before using it again.

- If the issue persists, contact the manufacturer for further assistance.

Conclusion

Keeping your cotton candy machine clean is crucial for its performance and longevity. Following the steps outlined in this guide will ensure that your machine continues to produce high-quality cotton candy. Regular cleaning and maintenance will help you avoid breakdowns and save on costly repairs.

With these simple yet effective tips, you can enjoy delicious cotton candy without any hassle.